Who we Are

FREEE Recycle Limited is a Waste Recycling and Rubber Manufacturing Company aimed at solving the problem of waste tyres by converting them into reusable rubber moulded products.

Established in 2018, our company is dedicated to addressing the challenges of waste tire management and promoting environmental protection through innovative recycling solutions. The Company aims to recycle 5 million scrap tyres annually hence, reducing the issues of waste tyre management in Nigeria.

FREEE Recycle Limited operates a state-of-the-art Tyre recycling, Rubber Mat making and Tile Manufacturing facility on Abeokuta Ibadan Expressway, Apata Ibadan, Oyo State, Nigeria. The facility is sited on a 2 5-hectare land. Since our inception, FREEE Recycle has recycled over 250,000 waste tyres, producing a range of vibrant rubber products suitable for various applications. From playgrounds to offices and warehouses, our products contribute to environmental sustainability while supporting local businesses and creating employment opportunities.

With our focus on sustainability and economic protection, FREEE Recycle has been able to make significant strides aligned with 12 of the UN Sustainable Development Goals (SDGs). Our operations contribute to responsible consumption and production (SDG 12), climate action (SDG 13), decent work and economic growth (SDG 8), and gender equality (SDG 5), among others

![]()

Vision: To Be the foremost Pan-African Recycling and Manufacturing Company.

Mission: To recycle products in Africa for African Consumption and to explore export potentials

Key Achivement

Our Production Process

Our Company follows a comprehensive and eco-friendly production process that transforms waste tires into high-quality rubber molded products. From meticulously collecting and shredding discarded tires to purifying the rubber granules, molding them into desired shapes, and stringent quality checks, every step is designed to maximize resource efficiency, minimize waste, and promote environmental sustainability. Throughout the production process, FREEE Recycle Limited adheres to strict quality control measures, ensuring that our products meet the highest standards of excellence. Our team of skilled professionals conducts rigorous inspections and tests to guarantee the safety and performance of the products.

The company’s commitment to sustainable practices extends from the beginning of the production process to packaging and distribution, championing circular economy principles.

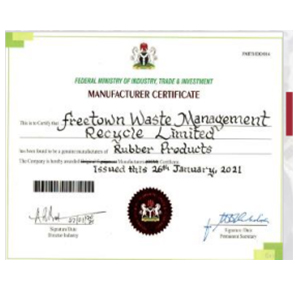

Certifications and Awards

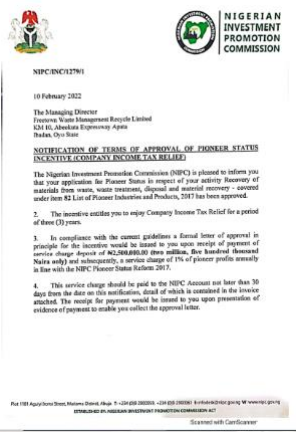

Pioneer Status Award

In recognition of our pioneering efforts in establishing the first recycling plant in Nigeria, the Company in 2021 received the Pioneer Status Award by the Nigerian Investment Promotion Commission (NIPC). This esteemed accolade acknowledges our trailblazing role in the country’s recycling industry and our contribution to environmental sustainability